Electroplating Racks

CornerStone Rack & Tooling has the processing technology and quality control required to build racks for chrome plating parts. CornerStone's equipment incorporates the latest technology and is operated by employees who have been trained in the process of building electroplating racks. Our core staff has over 100 years combined experience in the rack and tooling industry and ensures that quality is maintained throughout the manufacturing process.

CornerStone Rack & Tooling has the processing technology and quality control required to build racks for chrome plating parts. CornerStone's equipment incorporates the latest technology and is operated by employees who have been trained in the process of building electroplating racks. Our core staff has over 100 years combined experience in the rack and tooling industry and ensures that quality is maintained throughout the manufacturing process.

The CornerStone core staff experience is vital in building quality plating racks, especially when the substrate is plastic. The only school that teaches electroplating rack design is the "university of hard knocks", and with over a 100 years of combined experience the core staff at CornerStone are all "graduates". There are a multitude of factors that must be considered when building electroplating racks, and these factors can only be clearly understood through experience. A few of the critical factors are electrical current distribution, drainage, and warpage.

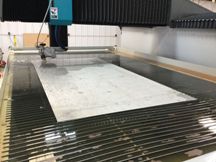

CornerStone Rack & Tooling provides fast and reliable service while maintaining a superior level of quality and design in building electroplating racks. Maintaining quality while building modern electroplating racks requires "state-of-the-art" equipment and training. CornerStone takes pride in maintaining our manufacturing facility with some of the best machinery and processes available in the industry. Our highly technical representatives spend an equal amount of time with our clients and on the CornerStone Rack & Tooling Shop Floor.

CornerStone Rack & Tooling can work with customers from the beginning stages of installing a conveyor in the plant to the final stages of production. CornerStone can custom design material- handling equipment for a new manufacturing process or redesign an existing system to achieve greater efficiency.

CornerStone Rack & Tooling can work with customers from the beginning stages of installing a conveyor in the plant to the final stages of production. CornerStone can custom design material- handling equipment for a new manufacturing process or redesign an existing system to achieve greater efficiency. CornerStone Rack & Tooling has the capabilities to put whatever finish is required on the conveyor racks or baskets to help reduce manufacturing defects that can be caused by handling and movement. The conveyor racks and baskets can be finished with a plastisol coating, a painted finish, or a combination of both finishing processes. The CornerStone staff has over a 100 years of combined experience in designing and implementing conveyor racks and baskets for the manufacturing and material-handling industries. For your next project, please contact us for a quote.

CornerStone Rack & Tooling has the capabilities to put whatever finish is required on the conveyor racks or baskets to help reduce manufacturing defects that can be caused by handling and movement. The conveyor racks and baskets can be finished with a plastisol coating, a painted finish, or a combination of both finishing processes. The CornerStone staff has over a 100 years of combined experience in designing and implementing conveyor racks and baskets for the manufacturing and material-handling industries. For your next project, please contact us for a quote. After careful analysis of the market, CornerStone Rack & Tooling has installed a plastisol coating system with some of the largest work parameters available anywhere in the industry. CornerStone can coat items with dimensions 9 feet long, 4 feet wide and 9 feet in depth with a weight not to exceed 500 pounds.

After careful analysis of the market, CornerStone Rack & Tooling has installed a plastisol coating system with some of the largest work parameters available anywhere in the industry. CornerStone can coat items with dimensions 9 feet long, 4 feet wide and 9 feet in depth with a weight not to exceed 500 pounds. CornerStone Rack & Tooling has the capabilities to provide all the tooling required to implement any industrial part's process from molding through surface finishing to the installation of the part on the finished product such as an automobile. We can create all of the tooling machines to meet the most demanding industry requirements.

CornerStone Rack & Tooling has the capabilities to provide all the tooling required to implement any industrial part's process from molding through surface finishing to the installation of the part on the finished product such as an automobile. We can create all of the tooling machines to meet the most demanding industry requirements. CornerStone Rack & Tooling LLC can provide all the design and layout services for surface finishing and material- handling projects. CornerStone Rack and Tooling is a one-stop shop that can work from industry part descriptions and line specifications to complete all the design services required to complete any surface finishing and material-handling project.

CornerStone Rack & Tooling LLC can provide all the design and layout services for surface finishing and material- handling projects. CornerStone Rack and Tooling is a one-stop shop that can work from industry part descriptions and line specifications to complete all the design services required to complete any surface finishing and material-handling project.